Prince’s Golf Club invests in sharpening equipment

Following a renovation project that has boosted Prince’s Golf Club in Kent’s course and course machinery, the club has invested in innovative new sharpening equipment.

Prince’s Golf Club in Sandwich, Kent, has invested in innovative new sharpening equipment to complement the recent renovations that have taken the club’s on-course offering to the next level.

The renovation project has resulted in restructured bunkers, tees and greens and, with further course investment in the pipeline, the club has reflected this with a major equipment upgrade.

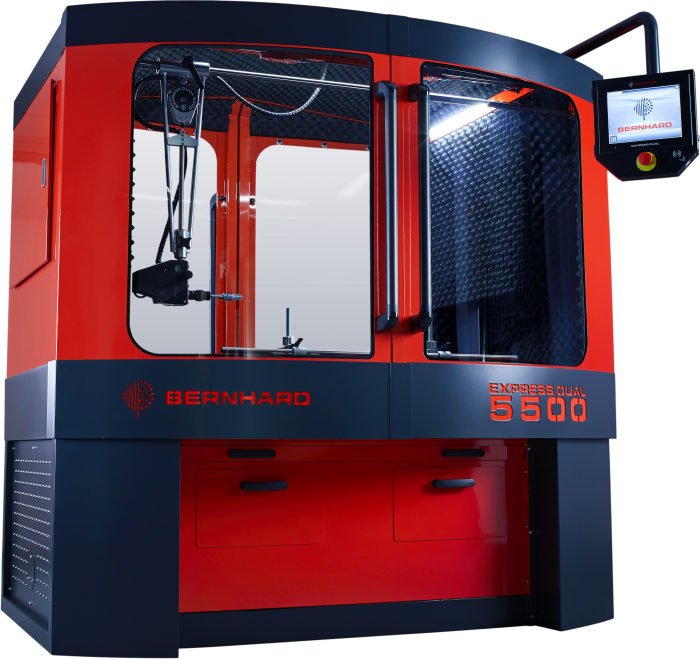

Keen to ensure that the turf on the club’s three nine-hole loops is at its healthiest to achieve the best quality, playability and aesthetic, Sean McLean, course manager at Prince’s Golf Club, has opted to upgrade the sharpening equipment to the latest Bernhard grinders.

The Express Dual 5500 and the Anglemaster 4500 were installed at the club in November 2019, providing the speed and accuracy of use that machinery manager Jon Bartlett was keen to achieve.

The automated reel surveying on the Express Dual 5500 will allow for maximum precision; it helps to determine wear and assists resolution of ‘coned’ and ‘barrelled’ reels – achieving the highest precision grind available in the industry.

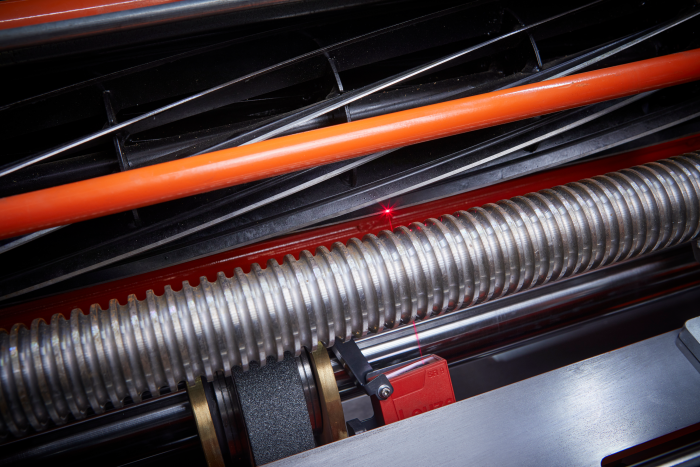

Laser measurement has been used for many years in the aerospace and automotive industry to measure large parts and assemblies, as well as improving industrial robot accuracy and precision.

Why would a laser surveying device be used in a grinder?

The laser surveying unit is used to highlight deformation and dynamic measurement. This is important because some modern-day cutting units rely on the cylinder to bed-knife being parallel within very tight tolerances to ensure optimum performance.

During continuous mowing or backlapping, the cylinder can be subject to coning which can only be corrected through precise grinding. The Bernhard laser surveying device will measure the cylinder to highlight any coning, thus allowing the grinder to remove the taper out of the cylinder with an optimised grind cycle.

In the scanning process, the laser will also measure the outer diameter of the reel. This gives the operator reassurance that the cylinders are within the manufacturer’s recommended specifications.

The new features of the machine include smart motors; high torque, load sensing motors with integrated position feedback that give users total control and flexibility on how they want to sharpen their mowing equipment.

The Anglemaster 4500 now benefits from variable grind motor and traverse motor speeds, allowing the machines to be totally adaptable to the type of blades being sharpened. Having flexibility in motor speed enables the user to optimise the speed of grind according to the type of stone chosen.

This, in conjunction with RFID (Radio Frequency Identification) technology, delivers consistency – no matter who uses the equipment.

RFID is an easy way to assign a unique identity to an object, meaning that each individual user can have their own settings programmed into a card no bigger than a credit card. The settings of each mower can also be uploaded onto the card, making it easy to recall previous settings and keeping consistently sharpened mowers to the same specification.

This means that turf / equipment managers can ensure the quality of cut is consistent without having to intervene, so even a newly-trained user with little experience of sharpening will be able to achieve the highest quality expected.

The combination of this unique technology makes the Bernhard sharpening systems the most innovative systems yet.

Speaking about the investment from Prince’s, Sean McLean said: “We are delighted with the new set of grinders. Accuracy and consistency are what we want to achieve on the greens. Being able to maintain a precise quality of cut through automated fleet set up is saving us time and in the long run will save us money.”

Jon Bartlett added: “Working with such precision machines is making my job even more enjoyable. And we know that we can keep our machines updated through the remote assistance at the press of a button. That is a very reassuring thought.

“Another important aspect that led to the decision of purchasing Bernhard’s top of the range grinders was the fact that our mower units could be ground in-situ therefore reducing the set-up time significantly. The quick set up along with the auto-traverse system means we have more time to perform other tasks in the workshop as we can leave the machines to sharpen the blades.”

A specialist in sports turf technology, Bernhard and Company is committed to providing leading turf care solutions to golf course and pitch care specialists worldwide. From blade sharpening systems to sports surface air movement and moisture control solutions and supplementary lighting solutions, the Bernhard product portfolio is focused on providing its global customer base with championship turf and world-class playability. Bernhard’s turf health solutions are used at top 100 courses and famous sporting venues around the world.

For more information, visit www.bernhard.co.uk

Let me tell You a sad story ! There are no comments yet, but You can be first one to comment this article.

Write a comment